Colleagues:

Ok, ok. I left you hanging. But, in spite of that, a number of you

offered your opinions ranging from the Hawthorne Method to Witchcraft! It

turns out that some of you studied Industrial Engineering while others studied

Theology! What a group.

Well, the engineering lesson I thought I learned (or actually

re-learned) was,

“Just because it’s in the drawings doesn’t mean its in the

hardware.”

I cut my teeth as a Liaison Engineer in a factory fixing the butches that

factory workers create when assembling airplanes at Boeing’s plant in

Seattle. That’s a whole different industry but whether it’s

optomechanical or aeromechanical, the principle is the same: Someone has

to assure that the engineer’s intentions are implemented. In our culture

that task usually falls to the Quality Assurance organization. Gene took

up that challenge. And, it felt just like Boeing’s factory, except for

the photons.

Thank you for hanging-in-there with me.

Enjoy early Autumn.

Al H.

9-20-16

Category Archives: Design

Optomechanics – Voilà. Ivory Analysis Produces Simple Fix

Colleagues:

Brutus to Cassius in Julius Caesar:

“There is a tide in the affairs of men which taken at the flood leads on to fortune. Omitted, all the voyage of their life is bound in shallows and in miseries.”

A product development project might be considered one of “the affairs of men” to which the Bard was alluding. My readers, however, should note that it was not “the affairs of men” that was Shakespear’s subject. Rather, it was “a tide” that Brutus’ declaration (and in fact the whole resulting drama) were about. Shakespear’s prescient observation has outlived him, at 400 years on the 23rd of April, for good reasons.

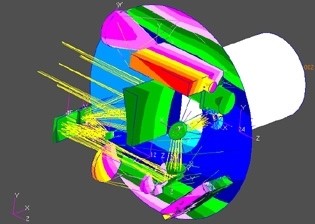

AEH guided a re-design effort, the goal of which was to markedly reduce the image jitter due to a random vibration excitation. The client’s analysts had assumed that “structural” damping was uniformly distributed through the system and had some difficulty simulating problems experienced during service. Fortunately, there was some accelerometer response data from earlier vibration tests and AEH was able to modify the distribution of damping in their Nastran model to better replicate that earlier data.

AEH

added the Optomechanical Constraint Equations

(via Ivory) and “Viola,” the model was now able

to reproduce the image jitter observed during service as well. Using the OCE to parse the Nastran displacement

vector identified the major contributors and a simple brace was added to the

design to stabilize the image.

None of this was planned. AEH happened to be on-site and

overhear a conversation at the coffee pot. A tide in the affairs of men

was forming. AEH, with Ivory, was

ready. As a wag might say, “Use it or lose it!”

Rejoice with me at William Shakespear’s 400th birthday!

Al H.

4-19-16

Optomechanics – Iterate Quickly Early

Colleagues:

Putting EO gear on Navy aircraft is a special sort of challenge, particularly

if it’s external stores. Not only does it have to pass the normal shock

and vibration tests, it has to pass the rigors of catapult launches and

arrested landings.

AEH was on the team that put active IR countermeasures into NavAir service.

The big challenge was the survival of the IR source which, until that time,

existed only in the research lab. We had to establish its fragility

threshold (by testing) and then design its installation to survive the

cats-n-traps of carrier service. The solution turned out to be custom,

AEH-designed, shock isolators and snubbers, one of AEH’s applications of the

principles of optical flexures. It was a six-degree-of-freedom

“kinematics” problem with about a dozen degrees-of-freedom in the

kinetic (design) solution, and non-linear at that. Great fun!

There aren’t always “canned” tools that the engineer can apply. This case required writing an interactive numerical integration routine that could be iterated quickly to explore the effects of the numerous design variables. Spreadsheet approaches were too cumbersome so source-code was written and compiled. The engineer could quickly modify the design variables and/or computational parameters and rerun the problem. This enabled a thorough survey of the design space, demonstrations of numerical stability and, ultimately, the determination of the most favorable design configuration.

It’s always good to have a source-code compiler around. It also helps to keep your other tools sharp.

AEH: Finding engineered solutions.

Spring must be coming. The apple trees are in full bloom!

Al H.

2-29-16

Optomechanics – A Unified Optomechanical Model

Colleagues:

The end of summer was a crazy time. Whew!

On my return from our San Diego meeting I helped develop the structural design for a new optical system. That seemed more important, at the time, than a biennial, “Thank you,” in a newsletter. Optics had to stake its claim for structural resources (stiffness) competing with the other disciplines. A Unified optomechanical model was the method.

We got it and the initial concept meets the

specifications now. So…

Now… I can take a moment to thank all of you for making this year’s

gathering in San Diego, of the International Technical Group on

Optomechanical Engineering, a resounding success: Thirty-two

published papers in a two-day conference, two outstanding invited speakers (one

on optical tolerancing, one on readiness assessments) and an evening meeting on

ground-based testing of space-based optical systems. SPIE’s

Optics+Photonics Symposium was the perfect host. They and I look forward

to organizing a similar event in two years, 2017, and we expect to see you all

there one more time.

Thank you, thank you and thank you, my colleagues. I apologize for having

ignored you all these weeks.

All is well at AEH and Autumn is safely here now.

School has started, the parents are on the loose again…

…and The Great Goblin awaits!!!

‘Tis time to keep your tools sharp!

Al H.

10-13-15

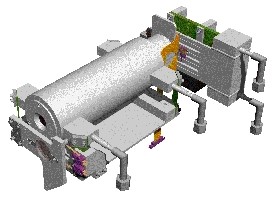

Optomechanics – Some Stuff AEH Built

Colleagues:

Every once in a while we at AEH get a chance to get our hands dirty. You

know, build stuff, install stuff, test stuff, fly stuff… Here’re a few

examples. The first is a “cryogenic” vacuum test facility for

qualification and acceptance testing of ISR focal plane arrays. AEH

designed, built and delivered them to fit into the client’s LN2 bell jar

system.

The second is an airborne, gimbal mounted,

spectrometer for environmental studies over the Arctic Ocean during

mid-winter. A team at AEH designed and built the gimballed sensor system,

installed it (in Alaska) into the flight vehicle (a helicopter) and got FAA

certification to fly the system in civil airspace.

Then there are the submicroradian-class adjustable (set-n-forget) fold mirrors

for ultra-precise alignment of wavefront bundles. No cold

“weather” here, just high altitudes and awesome vibrations.

AEH is known primarily for analysis, but it’s the non-linear stochastic process

of synthesis (better known as design) that makes it all work. That’s

engineering.

I’ll be expanding on this topic in a couple of papers next month at

Optics+Photonic in San Diego.

It’s all great fun!

Al H.

7-7-15

Optomechanics – The Route 66 of Optomechanics

Colleagues:

OK, enough about software. After all, we all run software. It’s AEH’s understanding of how to apply engineering tools, including software, that makes the difference.

To wit: design an airborne optical image correlator. Stabilize hyper-spectral imagers. Design aircraft structural-optical windows. Analyze detector cool-down times. Test metal-foil optical elements. Design nanometer-class alignment mechanisms. Minimize the thermal impedance in a laser cavity. Co-invent an infrared scanner. Stabilize a gas-dynamic laser cavity. Analyze thermal instability in lithographic lenses. Establish intellectual property rights in cinematographic lenses. Analyze dynamic stability of a free-space laser-com system. Design a stand-off optical vibrometer system.

I’ve written about many of these at one time or

another. But another big interest today seems to be, “Where do AEH’s jobs come from?”

Well how about Barrington, Huntsville, Albuquerque, Carson, Dallas, St. Louis,

Corona, Seattle, Palo Alto, Princeton, Los Angeles, Rochester, Tucson,

Anchorage, San Diego, Linthicum, Mountain View, North Hampton, Azusa and, yes,

even in Pasadena it’s been optomechanical engineering that AEH has done.

However you need help, wherever you need help AEH

is there.

N’Blarney ‘ere, b’Gorah!

Al H.

3-4-15

Optomechanics – Overcoming the Optical Lexicon for Mechanical Engineers

Colleagues:

Reflecting on the year just (barely) passed a couple of older stories keep coming to mind.

Early-on, a lens designer friend, Tom, asked me to mount an afocal triplet in a weapon sight. He said he wanted it to be on a kinematic mount. I hadn’t heard the term “kinematic mount” before so I did a little research. Mark’s Handbook had no entry. Maleev and Hartman’s Machine Design had no entry. Ham and Crane’s Mechanics of Machinery had no entry. Sears and Zemansky’s University Physics was not helpful. Finally, in J. L. Meriam’s Mechanics, Part 2, I found a partial definition, “kinematics … the study of the motions of bodies without reference to the forces which cause the motions….” I went back to Tom and asked him, “What kind of mount for optics in a weapon sight doesn’t consider the forces involved?” Well, he was patient in explaining his higher level of abstract reasoning and suggested that I expand my library.

Some time later I was sent by the Air Force to a

design review in Texas and to report what I found. I wrote you about this

a year or so ago. The physicists had designed one of the hottest

doubled-YAG lasers I’d ever seen and they requested that the cavity be

installed on a kinematic mount. The engineers complied with a classic

three-ball mount. It worked like a champ in the brassboard but the flight

unit was unstable. Everyone was perplexed. Well, it turned out that

the kinematic mount wouldn’t survive the service vibration so the mechanical

engineers had conveniently provided screws at each of the balls to lock them

out for flight.

In the first case Tom and I worked it out, I ate my humble pie and Tom put me

on his patent as a co-inventor. In the second case the Air Force lost

faith in the contractor and cancelled the entire project.

One of the challenges faced by mechanical engineers in the optics industry is

lexical: The engineer may hear what is said but not clearly understand

what is meant.

To address this challenge the engineer must ferret-out the acceptable

mechanical behavior, regardless of how it was originally expressed, and design

it into the required structures and mechanisms. It takes a little extra

digging but has proved to be a winning strategy.

And with that. . . A Happy New Year to you all!

Al H.

1-5-15

Optomechanics – Preventing Failure

Colleagues:

As an engineer I’m absorbed with understanding the ways that things fail.

It is often said that an engineer’s job is to make things work. Well, that’s nice. Tinkerers can do that too. The fact is that success rarely rewards an engineer while a single failure can nearly ruin him. What’s really needed from an engineer is to make things work every time. That’s a little different discipline.

Just ask Ray DeGiorgio, the GM engineer who’s taking the fall for the Chevy Cobalt ignition switch problem; or de Haviland, which nearly aborted the jet age, when a number of it’s Comet model passenger transports very quietly disappeared from the sky, without a trace; or the engineer who messed up the metrology on the Hubbell primary mirror.

So, as an engineer, I study how things fail in order to know how to prevent bad things from happening.

One key to failure prevention is early detection of possible failure modes. In optical systems, virtually all optical failures result from some defect in the mechanical implementation. These problems are never corrected by changing the optical prescription. (Well, almost never: There was the Hubbell primary mirror fix.)

Early detection requires special tools for the engineer. To detect optical problems the optics and the mechanics must be coupled by the engineer from the moment of conception. The results of this early coupling may only be estimates, but they’re essential. Few early engineering estimates provide elegant eye-candy, and to some people they may not be persuasive. But they give the engineer a sense of how to guide the design to the desired…, no, to the required destination. The estimates will be refined and formalized as the design matures and eventually may become deliverable analyses.

The tools the engineer uses must be able to grow with the project from early conceptual estimates to the final NASA, DOD or NTSB reports, a continuous flow of engineering evaluations using the same proven techniques with demonstrable quality within a growing database of design detail as the project progresses.

That’s AEH’s

mission and that’s why I study the way things fail.

And that’s why I’m going to have a terrific

Summertime!

How about you?

Al H.

6-27-14

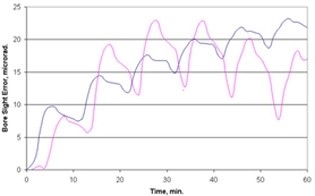

Optomechanics – Preventing Boresight Errors

Colleagues:

If engineering can be said to have a “purpose” it might be “to survey the available design spaces and guide the design process to avoid future failures.”

An especially tricky aspect of optomechanical engineering is avoiding unacceptable boresight errors among instruments during thermal transients.

One example is a target designator that was required to operate on a 50% duty cycle with a maximum on-time of five minutes. The boresight was important because the laser and the imager operated in different bands so the operator would not be able to “see” the laser spot in the FOV. The boresight error was required to be less than 15 microradians over one hour of operation. As shown in the figures the maximum boresight error was predicted to be 12 microradians after about 54 minutes (blue is the laser and pink is the imager).

In order to achieve acceptable stability it had

been necessary to add some bracing between the laser beam expander and the

imager’s primary mirror. Adjustments in the position of the laser had

also been necessary. These changes were made early enough in the design

process to avoid a major disruption of the program.

AEH/Ivory Optomechanical Modeling Tools

provided the critical link required to assure the system’s optical performance.

Baltimore was glorious and I had a great group of students. But it’s good

to be home!

Enjoy the fresh Springtime.

Al H.

5-27-14

Optomechanics – Early Viable Design Concept

Colleagues:

Ok, ok. I loaded you with a lot of details last week. But the good news is, “That’s all there is.” A few day’s work at the beginning of the project and you have a viable design concept with which to proceed and have developed an engineering tool to spot-check the design during it’s progress.

However, I must admit to an ulterior motive: Many of my optical colleagues only see the “eye candy” produced by SolidWorks, ProE or CATIA and are only vaguely (at best) aware of the “continuous stream of numbers” the mechanical engineer produces to assure the safety, reliability and optical function of his designs. The numbers have little eye appeal and optics should be visual at a minimum, right? Well, any draftsman can produce the eye candy but only an engineer can assure the resulting product.

I was able to enjoy my Easter weekend because I got that job put-to-bed. We know how to make it work. We’ll do some design checks as the design matures. Then we may put the optical behavior into the final FE model the structural engineers will create for their safety analyses. Or we may not. And that’ll be OK since we know that we’ll have good optical margins of safety.

Speaking of Easter, I hope

you all had a great weekend holiday.

And thank you for all of your support over the

years.

Al H.

4-24-14