Colleagues:

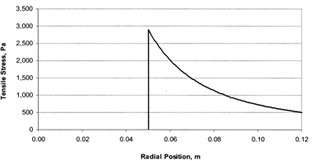

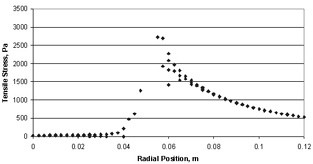

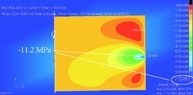

OK, AEH hit you in May you with analyzing the tensile

stresses in cemented glass doublets. Then AEH hit you in

June with analyzing the tensile stresses in ring-mounted glass

lenses. And you responded with numerous queries about AEH’s analytical

methods… but they were surrounded by a massive silence.

No one asked, “What’s the tensile strength of the glass?”

It’s a characteristic attitude in the optical industry, that

the strength of glass is not its problem, “Leave that to the structural

engineers.”

Well, surprise! The structural

engineers don’t care either. Glass, being brittle, is in

no-way a structural material. Structural engineers design with ductile

materials like steel and aluminum. The only brittle material they

routinely design with is concrete and they insist that it never see tensile

stresses. That’s why they invented

pre-stressed concrete: to eliminate

the tensile stresses!

The tensile strength of a glass is determined by its “fracture toughness,” a material property of the glass that can be measured in a test lab and is repeatable. However, among the silica glasses the values for fracture toughness appears to vary, based on the very limited data available, by factors between 3 and 5, depending upon the specific glass composition. It makes a big difference which glass is used in high-stress situations.

Ah, just one of the challenges

(and one of the joys!)

of optomechanical engineering.

Al H.

7-2-18