Colleagues:

If engineering can be said to have a “purpose” it might be “to survey the available design spaces and guide the design process to avoid future failures.”

An especially tricky aspect of optomechanical engineering is avoiding unacceptable boresight errors among instruments during thermal transients.

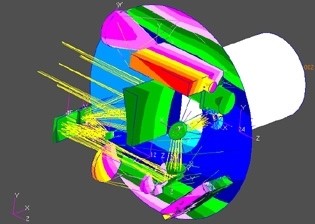

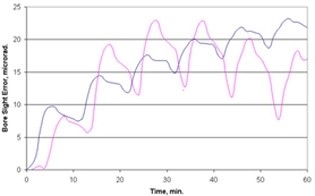

One example is a target designator that was required to operate on a 50% duty cycle with a maximum on-time of five minutes. The boresight was important because the laser and the imager operated in different bands so the operator would not be able to “see” the laser spot in the FOV. The boresight error was required to be less than 15 microradians over one hour of operation. As shown in the figures the maximum boresight error was predicted to be 12 microradians after about 54 minutes (blue is the laser and pink is the imager).

In order to achieve acceptable stability it had

been necessary to add some bracing between the laser beam expander and the

imager’s primary mirror. Adjustments in the position of the laser had

also been necessary. These changes were made early enough in the design

process to avoid a major disruption of the program.

AEH/Ivory Optomechanical Modeling Tools

provided the critical link required to assure the system’s optical performance.

Baltimore was glorious and I had a great group of students. But it’s good

to be home!

Enjoy the fresh Springtime.

Al H.

5-27-14