*A note from Teale Hatheway: As I pored over Dad’s emails to organize and archive AEH’s Optomechanics Newsletter, I came across this gem which, dated 7-18-18, was never shared. I also discovered an abundance of conversations sparked by these communications. It’s no wonder Dad enjoyed his work well past “retirement age”: your camaraderie combined with his intellectual pursuits gave him great joy. He would’ve called it “sport.” With well over 100 Optomechanics Newsletters published since 2006, the experience of compiling these brought me renewed clarity on Al’s life work. From AEH product announcements, to carefully worded client stories, to occasionally revealing his trade secrets, I hope you will continue to enjoy his wit and his wisdom here… So here we go! The last Optomechanics. I sure hope he finished editing it. Enjoy!

———–

Colleagues:

Put fracture mechanics to work for you!

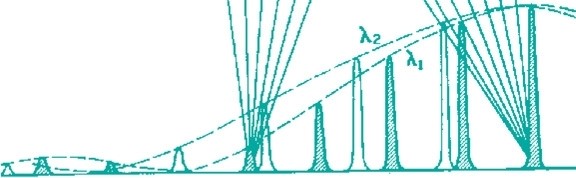

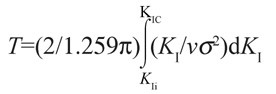

Fracture mechanics says that glass is sensitive to static stress corrosion fatigue effects. Glass parts have finite fatigue lives when operated in a normal moist environment. If the fatigue life, T, is defined as the time to fracture under the conditions of service, that life may be calculated from

noting that KIi is the initial stress intensity, KI

is the instantaneous stress intensity, KIc is the fracture toughness, v

is the instantaneous crack growth rate and the local stress, s, is time-variable and it is inside

the integral.

AEH recruits our Jade Brittle Fracture Analysis Tool, to

perform the numerical integration and determine T, the fatigue

life. For Jade it’s a

piece of cake!

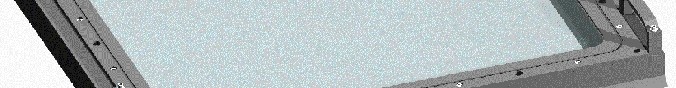

For instance, take this thermal-structural stress transient for an aircraft’s

window requiring 10,000 flight hours of service life:

FULL STRESS CYCLES AT FRACTURE= 3563

TIME TO FRACTURE= 44896587.75

SECONDS= 12471.274375 HOURS

CRITICAL INITIAL TENSILE STRESS= 55002270.5466022

INITIAL CRACK DEPTH= .000149

If the engineer applies a reasonable factor of safety, say

1.5, to the critical initial tensile stress (the ultimate load) it will provide

a proof test load (82.5 MPa in this case) that will assure the safety of the

window throughout its service life.

There’s no way to get there with closed-form solutions and it’s way too big for

an Excel spreadsheet. Jade

goes through the complete calculation in just seconds, allowing the engineer to

try various combinations of design variables to optimize a safe concept.

Jade Brittle Fracture Analysis Tool

Now available from AEH.

Al H.

7-18-18