Colleagues:

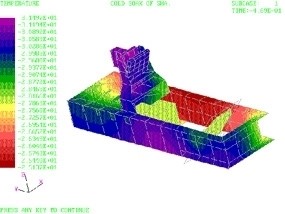

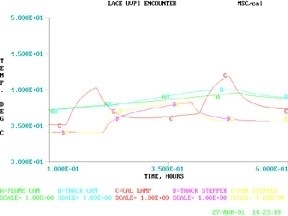

Ok, ok. I loaded you with a lot of details last week. But the good news is, “That’s all there is.” A few day’s work at the beginning of the project and you have a viable design concept with which to proceed and have developed an engineering tool to spot-check the design during it’s progress.

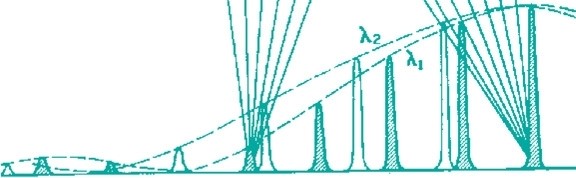

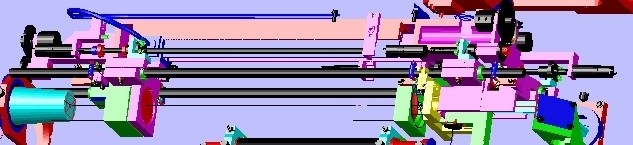

However, I must admit to an ulterior motive: Many of my optical colleagues only see the “eye candy” produced by SolidWorks, ProE or CATIA and are only vaguely (at best) aware of the “continuous stream of numbers” the mechanical engineer produces to assure the safety, reliability and optical function of his designs. The numbers have little eye appeal and optics should be visual at a minimum, right? Well, any draftsman can produce the eye candy but only an engineer can assure the resulting product.

I was able to enjoy my Easter weekend because I got that job put-to-bed. We know how to make it work. We’ll do some design checks as the design matures. Then we may put the optical behavior into the final FE model the structural engineers will create for their safety analyses. Or we may not. And that’ll be OK since we know that we’ll have good optical margins of safety.

Speaking of Easter, I hope

you all had a great weekend holiday.

And thank you for all of your support over the

years.

Al H.

4-24-14