Dear Colleague:

How accurately can your shop position a lens?

That is a question I’ve asked my students ever since I started teaching a class on optomechanical tolerancing of instruments, ca. 1990. It’s amazing, the answers I’ve gotten.

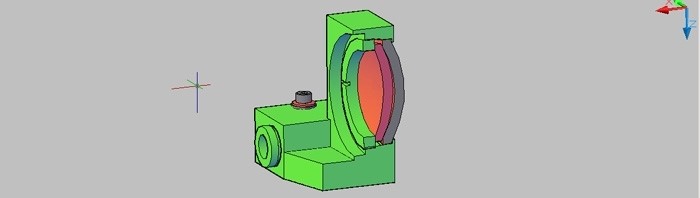

It recurred again recently with a client who had a contract to produce a number of ultra-wide field imaging instruments. The lens was composed of 19 glass elements arranged in nine singlets, four cemented doublets and two cemented triplets. The optical prescription was supplied by their customer as were the allowable alignment tolerances: ±0.005 mm in Tx, Ty and Tz and 20 arc-sec in Rx and Ry.

First, we had to establish the accuracy of their in-house fabrication processes. Getting the crib-notes out of the technicians was real sport. Then we had to find out the accuracy of their suppliers. The latter is usually much more problematic since you don’t really find out anything until you try to negotiate a contract (or, worst-case, only when the parts are delivered). Finally, we had to incorporate alignment mechanisms to make up the deficits, whatever we thought they may be.

You can put it all in a spreadsheet and have great fun with it!

Also back in the ’90s, I was asked by one of the shakers-‘n’-movers in the

optical industry if I would publish a summary of the state-of-the-art of

achievable manufacturing accuracy for the various manufacturing

processes. It would be a great boon to the industry, he said, and indeed

it would. Unfortunately, manufacturing accuracy is not a fixed quantity.

Not only does it vary over time but also with geography, supplier and price

(not to mention attitude). And the variation with each of these is not

always favorable.

In the above example one of my client’s suppliers (actually, their preferred

machine shop) refused to adopt innovative techniques that could provide the

required accuracy, presumably because they had committed to a price before they

knew what was to be demanded of them. Or maybe they didn’t have the

confidence in the precision of their machine tools that I expected. Or

maybe they had too much work and this would disrupt their shop practices.

Who knows?

So, back to the spreadsheet and more fun! Thumb the yellow pages and

buyers’ guides. Explore changes to the construction materials.

Re-tolerance the optics? Call the customer? In some ways good

engineering resembles good accounting; keep pushing the numbers around until

you find a workable combination.

That’s engineering, and one more amazing

answer to that question.

Cheers.

Al Hatheway

5-22-08