Colleagues:

Well, Ok. It’s not that AEH

hasn’t seen broken glass this past year, it’s just that it hasn’t been AEH’s glass that broke. Cemented

doublets were the principal excitement. AEH’s

research indicates that, for a quick check,

tensile stress in the glass =~ (E1 + E2)/2 x (alpha1 – alpha2) x deltaT

and

shear stress in the adhesive =~ 2/3 x tensile stress in the glass.

If stresses are marginal the engineer may then want to adjust for the edge thicknesses of the lenses and the Poisson’s ratios of their glasses. The peak shear and tensile stresses occur at or near the edges of the lenses. The only dimensions that influence the stresses are the edge thicknesses. Center thickness and diameter have little influence on the stresses at the edges.

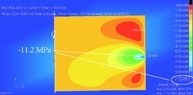

Radial Tension Shear Axial Tension

Does it all seem spooky? Well, I’ll take you through the gory details in my tutorial,

“Optomechanical

Analysis,”

August 21st in San Diego at SPIE’s Optics and Photonics Symposium.

And, I’ll toss in, just for you, the latest details on the stresses in ring-mounted glass lenses including a close-form solution and a finite element simulation!

I’ll see you

all in San Diego. Bring your sun-screen.

Al H.

5-4-18