Colleagues:

Ah… That Joyous Season is upon us once again.

In the Hatheway household it runs from about now ’till Twelfth Night,

our daughter’s birthday. We’re careful to let Guy Fawkes Day slip quietly

by before we start to celebrate. (We’re all for Parliament but burning

effigies is a real downer.)

And, what a grand year it is shaping up to have been (yes, in the future

perfect tense). Speaking of which…

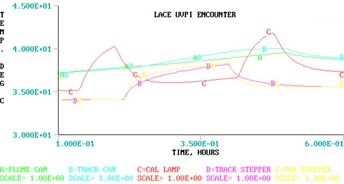

AEH fixed the wedge caused by

thermal gradients….

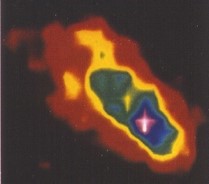

… witnessed the solar eclipse in the Alleghenies…

… chaired a conference in San Diego….

… was snowed in Massachusetts…

… and got lost in Irvine.

That last one was a real embarrassment since

your author was raised about 20 miles from there. But that was before Irvine

“grew up.”

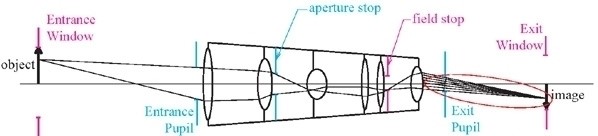

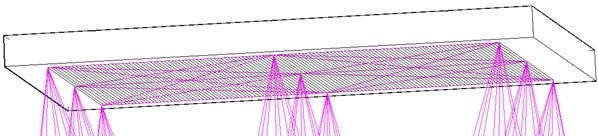

Ivory and Jade are having a

terrific year also, assuring the performance of systems from zoom lenses to

gimbal controls and assuring the safety of critical lenses and windows by

helping designers select suitable materials and specify proof tests. No broken

glass so far.

So, here’s a wassail to you, one and all, for your companionship and

cheerfulness throughout the year.

God Bless you, Tiny Tim!

And everyone else, Enjoy! Here we

go-o-o-o-o-o…..

Al H.

11-10-17