Colleagues:

This is a tale about the power of flats.

The IR sensor was out of focus and I drew the straw that said, “Measure

the contraction in the focal plane support structure between room temperature

and 80 K.” Others drew different straws and the project turned

itself inside-out to discover the root cause of the focus problem. This

system did not have an on-orbit focus control mechanism. (Now, now!

I hear you clucking your tongues. But, do you know how many successful

systems do not have focus controls? Enough! It’s my story!)

Finally, the various straw-drawers were convened and none could find a

millimeter of focus error, anywhere, adding up all our contributions.

After the meeting I was assigned to another project, as happens in large

firms. I eventually left the firm not knowing how the problem was resolved.

Some time later, at an Optical Society meeting, I was sitting with one of my

erstwhile compatriots reminiscing. He declared that the problem had been

resolved and was not a design problem at all, just an unfortunate

artifact of the test setup.

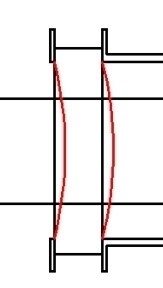

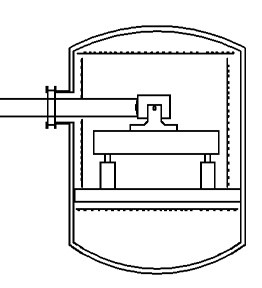

The germanium window in the vacuum tank sagged under the influence of the

outside pressure (see the figure). The resulting curvature of the surfaces

created a meniscus lens with a small optical power ( about -5.E-08 diopters)

but enough to cause the image to fall behind the focal plane by over a

millimeter and send the project team into its flurry.

It’s a simple thing to check: One equation from Roark for the deflection;

a little geometry for the radius of curvature; the basic lens equation for the

focal length and Ivory (or Zemax

or CodeV or Oslo if you insist) for the focus error. This firm was one of

the old-line firms of Southern California aerospace and they were in space

before I was out of college. This was not their maiden voyage to low

earth orbit.

My compatriot’s uncritical views were colored (in my judgement) by his

philosophical training as an optical designer. As an engineer I was more

jaundiced: The engineer who designed the test should have seen this

one coming and accommodated it (defocus the collimator, introduce a

corrector lens, something). But, it just got lost among the various

groups who participated in the project.

My advice to optomechanical engineers: Beware of flat optical elements;

windows, wave plates, fold mirrors, etc. Everyone, I mean everyone,

is checking the components with any optical power. The un-powered flat

components get short shrift. The results are often not seen until very

late in the program and then they raise Holy Havoc with the engineer’s evenings

and weekends.

I pass this anecdote along to you partly as a cautionary tale and partly as a

celebration of the insight I gained from that compatriot one evening over a

pleasant dinner at an Optical Society meeting. That insight, pay extra

attention to all the “flat” elements, has saved my buttons

many times over the years since I left my former firm, uncertain about the

sensor that didn’t focus. Thanks, Bob.

The Holidays are coming and I hope you all enjoy a festive Season filled with

friends, family and warm camaraderie.

Al Hatheway

11-16-10