Colleagues:

When performance is crucial the engineer uses tools to assure it. Let me show you:

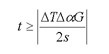

Say, we need a hyperspectral design with a 60 cm entrance pupil and stabilized to less than 15 ur, rms, LOS error in object-space. We have the physical prescription. How to get started?

The first thing I do is run the physical prescription data through AEH/Ivory Optomechanical Modeling Tools and import them into MSC/Patran-Nastran to start a system model (1). The pink lines represent the optics and the yellow lines are structural bar elements with lumped masses.

It’s a crummy “visual” but a very important first step. I validate the model with rigid-body checks. Then I run the model through random vibration adjusting the properties of the bar elements (areas, inertias, materials, etc.) until AEH/Ivory-in-Nastran satisfies the LOS performance requirement (12.3 ur, rms, in this case) with a reasonable combination of properties.

Next I incorporate solid models of the optical

elements and replace the simple bars with more complicated beam elements

(rectangular and circular tubes, some tapered) and optimize their wall

thicknesses to maintain the AEH/Ivory-in-Nastran LOS performance

(2). I now have an estimate of a housing geometry (masses, dimensions,

thicknesses) that will meet the LOS performance.

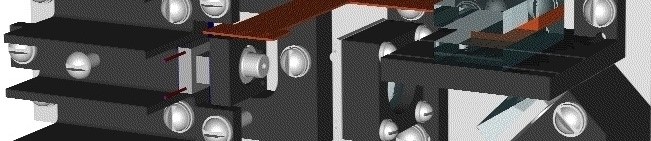

The CAD engineer has decided on a three-piece housing design; an objective, a compound

elbow and a detector. The first section we develop is the compound elbow

that holds the grating. The CAD engineer makes a model which I import

into the system model. When we have an elbow design that maintains the AEH/Ivory-in-Nastran

LOS performance in the system model, (3), we move ahead.

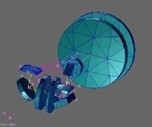

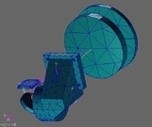

We design the objective and the detector sections next, import them, one at a

time, into the system model. We run the model through random vibration

adjusting properties to maintain the AEH/Ivory-in-Nastran LOS

performance before proceeding. Finally, (4), we have developed a

three-piece optical housing design through an iterative engineering process

that supports the required LOS stability.

That’s optomechanical engineering with tools. No surprises. No excitement.

Just getting where we need to go, working from the optical prescription.

Now, to play a little…

Oh! Joyous Summertime.

Al H.

7-7-14