Colleagues:

Optics is a crazy industry. We’re so dedicated to the digital computer

that we often overlook underlying realities. That’s especially true in

the mechanical engineering art of heat transfer. Management structures

have insisted on each discipline using its own software which has Balkanized

the disciplines of structures and heat transfer: i.e., the temperatures must be

analyzed in a finite difference (FD) code and the results imported to a finite

element (FE) code. The importation involves extensive extrapolation and

interpolation of the FD data to the much larger (often by two or three orders

of magnitude) of the FE data-set and it can lead to some peculiar results.

AEH has long preferred a more Unified

approach: Select a code that can do them both, usually an FE code, and

use engineering judgement to adapt the other discipline (usually a few boundary

temperatures). It usually requires several runs of the problem to assure

that the underlying assumptions of the adaptation were appropriate but they go

much faster than the Balkanized approach (and, often, more accurately for the

optics behavior).

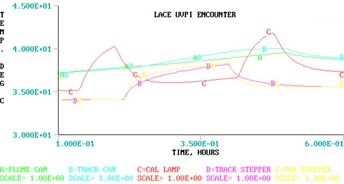

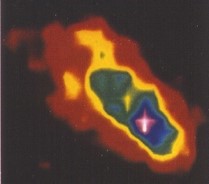

It’s the thermal-structural-optical method I used on the LACE Ultra-Violet

Plume Instrument, which made Aviation Week’s75th

Anniversary Issue. Check out the UV plume

image from AW’s cover, above!

More recently, a colleague was directed to thermally analyze an optical

system in CFD and I was to apply his temperatures and gradients to calculate

the boresight errors among the optical instruments. Well, what he was

handing me made no sense at all. So, I added heat transfer terms to my opto-structural

FE model and ran the operational transient of concern to the project. The

thermo-structural-optical results were spot-on.

There are a lot of ways that an engineer needs to keep his tools sharp.

And they require maintaining confidence in the analytical methods as well.

More later. Happy Holloween!!!!!

Al H.

10-23-17