Colleagues:

How does a mechanical engineer identify problems early? He or she runs estimates and analyses, maybe solving two or three degree of freedom (DOF) lumped-parameter problems via simultaneous equations in a spreadsheet. Estimating surface temperatures on the outside of a cast housing comes to mind with simultaneous radiation, convection and conduction needing to be considered.

But, throw in optical imaging behavior and the number of equations explodes. The optomechanical engineer deals with not only the structural and thermal equation but also the 49 equations for each optical element’s effect on the system’s image. For even modest optical systems this swamps the engineer’s conventional methods. Who’s going to solve a 100+ equation problem in a spreadsheet?

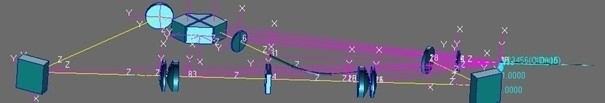

It’s one thing to write about lumped-parameter optomechanical modeling. It’s a whole other thing to actually do it. The optomechanical engineer needs optomechanical tools. Here’s a “relatively simple” 874 equation (DOF) optical/structural lumped-parameter model:

All of the 784 optics equations were modeled in AEH/Ivory and imported to the MSC/Nastran lumped-structural model (90

equations) for numerical solution. The Nastran

run identified critical thermal alignment challenges, the solution to which enabled a successful telecoms product.

Assembling and running simple lumped-parameter optomechanical models saves

budgets, saves schedules and snatches success from the jaws of failure.

That’s engineering.

If you have questions give AEH

a call.

I’ll talk more about this in San Diego at SPIE’s

Optics+Photonics Symposium, come August. We’ll have a two-day conference, poster sessions and an evening meeting

of the Optomechanical Engineering Technical Group. It’ll be a

great time with technical exhibits, banquets and camaraderie. I hope to

see you all there.

Meanwhile… identify problems early, stay on top and keep your tools sharp!

Al H.

6-10-15