Colleagues:

Skeptics like to tease me about using my own software tools to create

optomechanical models in finite element codes. I could simply use the

coefficients provided by the optical designer, they suggest. In a way

they’re right. But I have found that my software allows me to enjoy more

of my evenings and weekends. Let me explain:

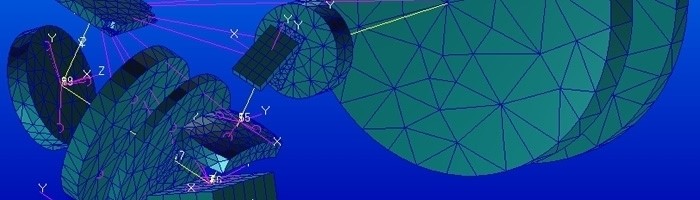

The task is to incorporate the optical image formation properties into a

structural finite element model. Rigor is required because small modeling

errors can create large misleading results in the subsequent analyses. A complete

set of coefficients and congruent descriptionsof the geometries

are essential for a properly formulated optomechanical model. This

allows the optomechanical engineer to validate the integrity of the entire

system model with what are called “rigid-body checks.”

But, how to satisfy the “complete” and “congruent”

criteria? Well, I use Ivory.

Now, about the importance of those rigid-body checks:

First, structures: A rigid-body

check exercises the otherwise unconstrained complete model in three

translations (Tx, Ty and Tz) and three rotations (Rx, Ry and Rz). The

check discloses malformed elements, erroneous constraints and other errors,

which the engineer must correct to have confidence in subsequent analytical

results. It’s a tried-and-true method for checkout of structural models.

Then, optics: In the optics domain the image motions on the

detector during rigid-body checks should be either computational zeros or the effective focal length depending

on the status of the object being imaged. If the model’s image motions

contain anomalies (motions other than 0. or the efl) in any of the whole

model’s rigid-body motions then the model is poorly formed and the

optomechanical engineer must correct it before relying on any subsequent

results. This is a tried-and-true method for checkout of optomechanical

models.

Without a complete set of optomechanical coefficients and assured congruent

geometries it is very difficult to tell whether any anomalies are artifacts of

geometric differences or of inaccurate and/or missing coefficients. Small

imaging anomalies can create large errors in the analyses. But even small

(or perhaps “Especially small”) anomalies can be very time consuming

to find and correct. There are many potential sources of small errors.

That’s where my software lets me enjoy evenings and weekends. I start

with a complete set of Ivory’s

coefficients and congruent geometries (from the optical designer’s

prescription), check their validity in a simple finite element model (with

rigid-body checks) before putting them into the structural engineer’s larger

model of the system.

When the two are married, Voila! Bliss! Well, fewer

surprises anyway, and more evenings and weekends for me.

So, don’t spend your Holidays in front of your work-station when you should be

with your family and friends.

The Season’s Cheer to you all. I can

almost hear the sleigh bells coming.

Al H.

11-12-13