Model 7007 Track-pad ™ Micrometer Tip Cushions and Anvils

CALIBRATED ELASTICITY APPLICATION NOTE

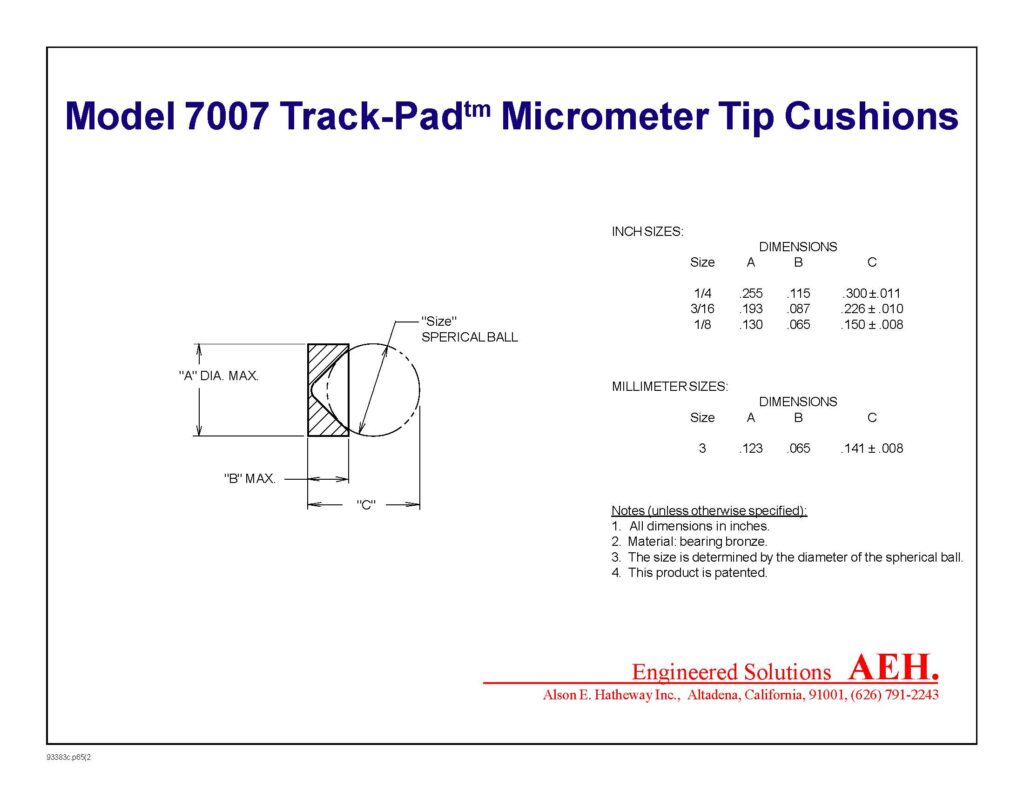

Model 7007 Track-pad ™ Micrometer Tip Cushions

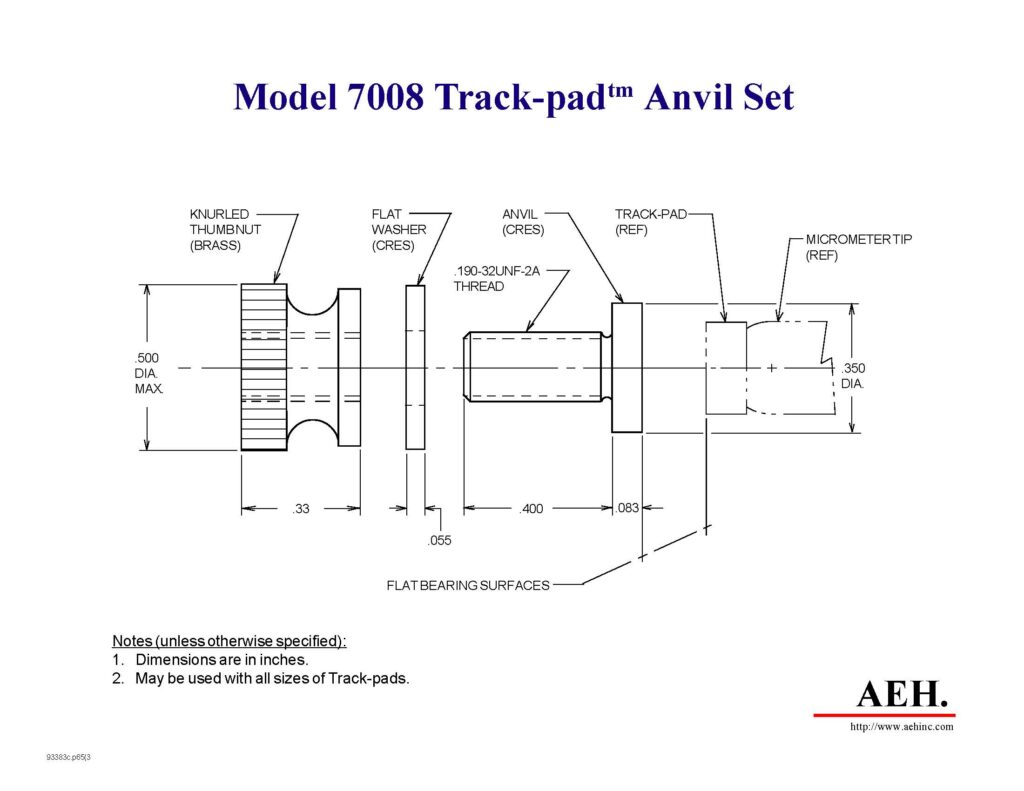

Our Model 7007 Track-pad micrometer tip cushions are designed to provide the user with the greatest lifetime and the highest precision from conventional micrometer adjustment and drive mechanisms. The Track-pad is designed to receive a spherical tip on a micrometer spindle (such as our model 2001-1 micrometer). The anvil is secured to the structure that is being driven by the micrometer (it is provided with a .190-32UNF threaded stud for this purpose). The Track-pad rides between the micrometer tip and the anvil . The Track-pad may be used without the anvil if a suitabe flat surface is provided on the driven portion of the mechanism.

Eliminates wobble effects

Extends micrometer life

Because of its unique design the action of the Track-pad will reduce the nutating force caused by the eccentricity between the micrometer tip’s contact point and the center of rotation of the micrometer’s spindle. The reduction is between two and three orders of magnitude for conventional micrometer installations. The Track-pad virtually eliminates of the micrometer as a source of cross-track motions in most mechanisms.

The Track-pad dramatically extends the life of micrometer tips used for driving stages, linkages and mechanisms of all sorts. Contact stresses between a spherical tipped micrometer and a flat driven surface may be in the range of 150,000 psi. to 400,000 psi. Typically a stainless steel micrometer tip is used against a flat stainless steel bearing surface, a very poor tribological combination. The surface stresses rapidly gall and spall the surfaces until they become so rough as to be unserviceable. The Track-pad reduces these stresses by an order of magnitude or more, replacing the point contact configuration (spherical tip to flat surface) with line contact and surface contact configurations (on opposite sides of the Track-pad). The Track-pad also replaces the stainless steel-to-stainless steel interface with two bronze-to-stainless steel interfaces, each being a tribologically superior combination.