Colleagues:

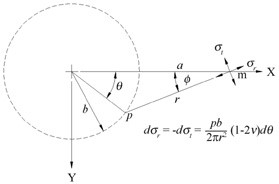

AEH has solved elastic

theory’s differential equations for the tensile stresses in glass lenses

mounted in threaded metal rings, and it’s

good news.

Paul Yoder had originally proposed Delgado and Hallinan’s 1975 solution (Opt.

Eng. 14) but their solution gave very high tensile stresses in the

lenses, high enough that virtually all such lenses should have fractured.

None of my ring mounted glass lenses had ever suffered that fate. I

surveyed a number of my colleagues and none of them recalled a ring mounted

glass lens fracture.

Delgado and Hallinan’s work was flawed. To correct their flaw would

require a new solution to the equations of elasticity that honored the

appropriate contact geometry. AEH

finally made it happen and the result is surprisingly simple,

s = p(1-2u)/b,

where s is the peak tensile stress, p is the

linear ring load, b is the radius of the contact ring and u is

the Poisson’s ratio of the glass. This stress is three-to-four orders of

magnitude lower than that predicted by Delgado and Hallinan.

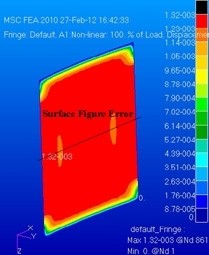

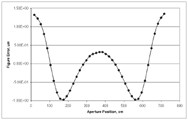

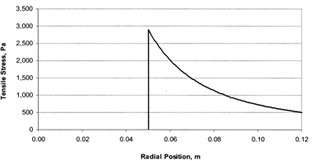

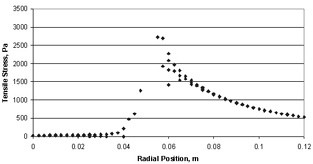

Using Nastran AEH was also

able to verify the general shape of the stress distribution in spite of

Nastran’s notorious difficulty at the point of load application.

Closed-form solution >>> Nastran solution

To learn more you have choices: Either download AEH’s peer reviewed paper from SPIE [Optical Engineering 57(5), 055105] or go through the gory details with me in my tutorial,

“Optomechanical Analysis,”

SPIE’s Optics and Photonics Symposium in San Diego

8:30 AM to 5:00 PM on the 21st of August.Cheers!

Al H.

6-6-18